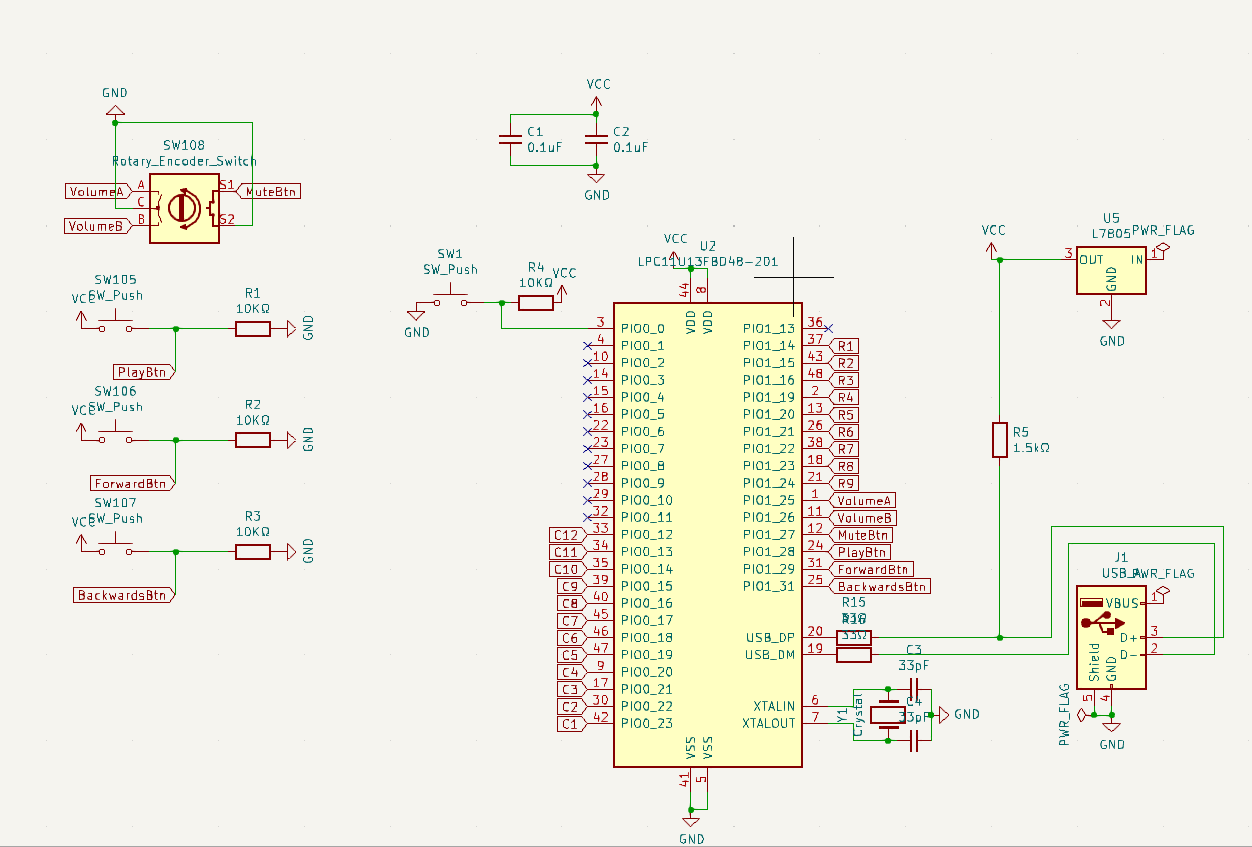

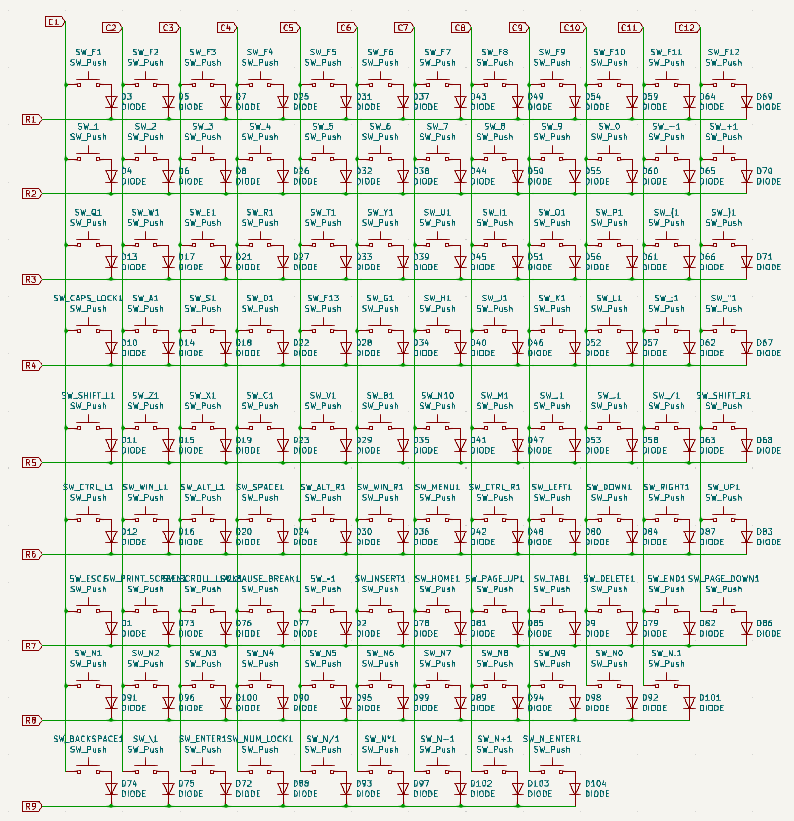

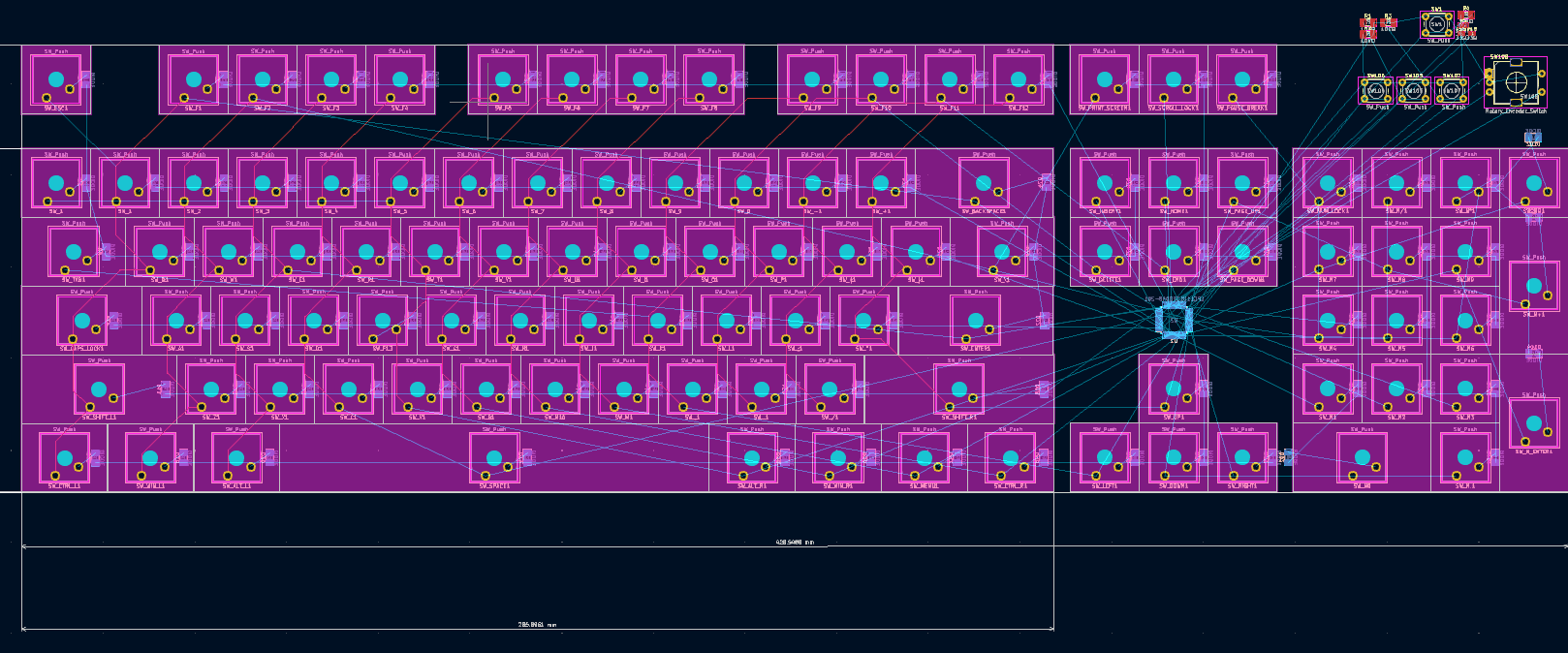

I designed a custom mechanical keyboard PCB in KiCad with the schematic and in-progress PCB layout shown above. The board is built around a diode-protected switch matrix and a USB-enabled microcontroller, the LPC11U13. This chip was intended to run the open-source QMK firmware to meet the same specifications as most other marketable keyboards.

My Goal:

During the pandemic, I was getting more interested with mechanical keyboards and how my everyday electronics worked. To gain more knowledge on this subject, I decided to create a programmable keyboard that could be assembled and flashed like a commercial product. That meant supporting a standard key layout, mechanical stabilizers for large keys, and reliable USB communication while staying economical for fabrication.

During the pandemic, I was getting more interested with mechanical keyboards and how my everyday electronics worked. To gain more knowledge on this subject, I decided to create a programmable keyboard that could be assembled and flashed like a commercial product. That meant supporting a standard key layout, mechanical stabilizers for large keys, and reliable USB communication while staying economical for fabrication.

The Schematic:

The schematic defines an 8×12 key matrix with diodes on every switch to prevent ghosting, plus a rotary encoder with push button for volume and media control. I added a crystal oscillator for USB timing, ESD protection, and a clean power supply section.

The schematic defines an 8×12 key matrix with diodes on every switch to prevent ghosting, plus a rotary encoder with push button for volume and media control. I added a crystal oscillator for USB timing, ESD protection, and a clean power supply section.

Business Research :

To keep the board practical and low-cost, I researched common keyboard standards—key sizes, spacing, and stabilizer footprints—so it can use off-the-shelf keycaps and cases. Most off-the-shelf products were not feasible for a business product. Instead, I found myself scouring through Aliexpress and Alibaba, exploring small business rates and the logistical and financial improvement of manufacturing at scale.

To keep the board practical and low-cost, I researched common keyboard standards—key sizes, spacing, and stabilizer footprints—so it can use off-the-shelf keycaps and cases. Most off-the-shelf products were not feasible for a business product. Instead, I found myself scouring through Aliexpress and Alibaba, exploring small business rates and the logistical and financial improvement of manufacturing at scale.